Cooling Tower and its Classification

A cooling tower is a heat rejection device that uses water to dissipate heat from industrial processes, HVAC systems, and power plants, transferring heat from water to air through evaporation. Cooling towers are classified into two main types:

- Open Circuit (also known as wet cooling towers)

- Closed Circuit (also known as dry cooling towers)

Problems in Cooling Tower

Here are four common problems that can occur in cooling towers:

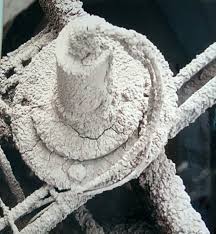

Scaling and Fouling: Mineral deposits and biological growth can reduce heat transfer efficiency and clog water distribution systems.

Corrosion: Water and air can cause corrosion of tower materials, leading to structural damage and leaks.

Biological Growth: Bacteria, algae, and fungi can grow in the tower, causing odors, health risks, and equipment damage.

Drift and Blowdown: Excessive water loss through drift (water droplets carried away by air) and blowdown (intentional water discharge) can increase water treatment costs and environmental impact.

Corrosion and Scale Control in Cooling Tower

Our Scale & Corrosion Inhibitors, for Different Hardness of Water:

- For Soft Water – C-302

- For Hard Water – C-301

- For Very Hard Water – C-305 (C-304 for CCM)

Moving on to Corrosion Problem, Corrosion Can Be Caused by Many Factors:

If acid is added to tower water to maintain carbonate alkalinity, an overfeed of acid can cause severe corrosion in the condenser.

To avoid this corrosion, we recommend not to use an acid feed to control scale-forming impurities.

Microbiological Growth Control in Cooling Tower

Microbiological growth in cooling towers refers to the proliferation of microorganisms such as bacteria, algae, fungi, and protozoa.

In the tower’s water system, these microorganisms can form biofilms, slimes, and mats that can cause problems like corrosion, fouling, and health risks (e.g., Legionnaires’ disease), as well as reduce the tower’s efficiency and overall performance.

Chemical products used to control microbiological growth in cooling towers include biocides such as chlorine, bromine, and ozone, which kill or inhibit the growth of microorganisms. Algaecides like copper sulfate and quats are used to control algae growth. Fungicides and bactericides like isothiazolinones and DBNPA are used to target specific types of microorganisms. Additionally, bio-dispersants like polyphosphates and polyacrylates are used to break down and remove biofilms and slimes.

Our Products:

- C-520

- C-540

- C-500

- C-530

- C-570

Bio Dispersant

Our bio-dispersants are effective in removing algae and slime masses from cooling towers by breaking down and dissolving the organic matter.

- C-580